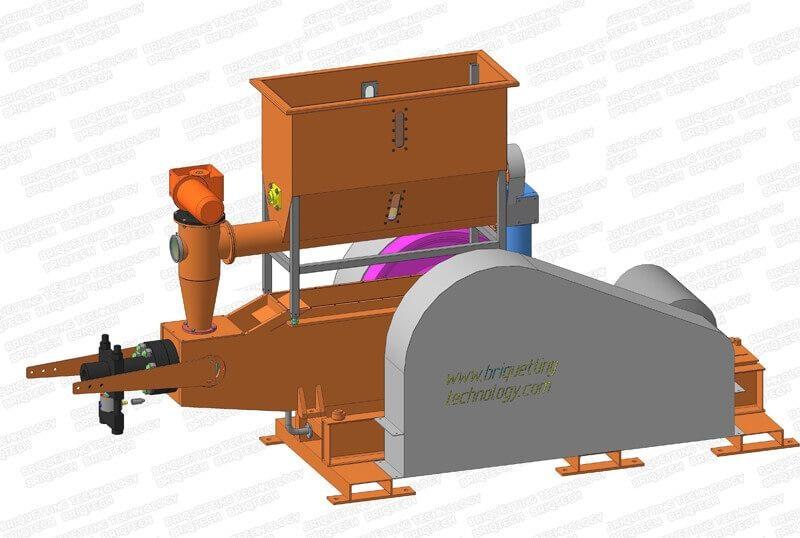

BriqTech mechanical briquetting press model: BT-060-400 Mechanical briquetting press BriqTech model: BT-065-500

Mechanical briquetting press BriqTech model: BT-070-800 Mechanical briquetting press BriqTech model: BT-070-800Max

Rapeseed-straw briquetting machine, BriqTech series - Sawdust briquette press, BriqTech series - Sawdust briquetting machines, BriqTech series

Rapeseed-straw briquetting machine, BriqTech series - Sawdust briquette press, BriqTech series - Sawdust briquetting machines, BriqTech series

|

|

|

|

Mechanical briquetting press BriqTech model: rapeseed-straw mechanical - Sawdust mechanical briquette presses Mechanical biomass briquette press - Sawdust mechanical briquetting presses

Biomass waste briquette press - Forest waste briquette machine

Why choose a mechanical piston briquetting press, operated by a flywheel, instead of a hydraulic press or an extrusion press?

The principle of the mechanical briquetting press lies in the crank mechanism that converts rotational motion into linear motion of the piston pusher of the briquetting press. The raw material is compressed in a forming channel without adhesives or binders, resulting in briquettes (solid fuel). To maximize profits from briquette production from biomass waste, the robustness and quality of the equipment, as well as the raw material and business partners, play a crucial role. Briquettes are used in heating systems, stoves, wood-fired ovens, and have higher calorific value and efficiency compared to firewood, making them 100% ecological!

A mechanical piston briquetting press has a lower purchase cost, lower operating costs, and a longer lifespan compared to hydraulic presses or extrusion presses with resistance (Pini Kay briquettes). The "BriqTech" mechanical piston briquette press of the "Nestro" type is the right choice for any type of raw material containing lignin.

"BriqTech" briquetting presses models: BT-065-500, BT-070-800, BT-070-800Max now receive a new optional feature: Hydraulic automation for the tightening of the briquette press head and preheating/heating of the conical sleeve. This includes preheating the conical sleeve before starting or during the operation of the briquetting press -> Automatic hydraulic tightening or releasing of jaws -> The automatic hydraulic mode greatly simplifies the operation of the press for briquette production. This feature allows the press to produce more kilograms of briquettes per hour and ensures a more stable production without operator intervention.

Today, the desire to profit in this field requires just an impulse to initiate a successful business.

A good example is the utilization of biomass waste and the production of briquettes from forest waste and plant residues containing lignin.

The trend demonstrates that businesses initiated in this sector enjoy profitability, but the main aspect is the high quality of briquette production equipment. "Briquetting Technology" as a manufacturer respects the quality of the equipment, while offering the best innovations and complete solutions on the market.

The basic principles for choosing briquette production equipment are functionality, reliability, user-friendliness, availability of spare parts, service, warranty, and after-sales support.

"Briquetting Technology," in the "BriqTech" series, offers the highest quality briquetting machines for briquette production. It provides the opportunity to create briquetting lines for processing wood, sawdust, straw, and other lignin-containing waste.

We return to our plan of building your successful business.

The first step is the raw material.

Currently, the variety of materials used to make briquettes is extensive: wood waste, sawdust, tree roots, plant residues, wheat straw, sunflower husks, rapeseed, soybean, corn stalks, etc.

To obtain a high-quality end product (briquettes), the raw material must be adequately dried and homogenized in terms of moisture content, unless an aerodynamic dryer or rotary dryer is used. The moisture content should be around 10-12-14-16%, and the fraction (granulation) of the raw material should be between 3-8 mm. Otherwise, drying and shredding of the raw material are necessary.

The next step is having an appropriate space for briquette production. You should also consider the volume and dimensions of the briquetting equipment. As a guide, a minimum space of 120-150 square meters, a 400V three-phase power supply with a capacity of up to 100-150 kW, and personnel (2-4 employees depending on the briquetting line and working shifts) are needed for the proper installation of the briquetting equipment.

Another crucial aspect to mention is the consumption of 50% of the total installed power. Compensating for inductive reactive energy through capacitor banks significantly reduces the cost of energy bills.

This guide provides you with some recommendations for starting a successful business, and we are here to assist you with any questions or clarifications.

"Briquetting Technology" offers a 24-month warranty from the start of operation. The post-warranty period is a minimum of 10 years.

A crucial aspect in ensuring the proper functioning of briquetting equipment is the efficient supply of necessary spare parts. From this perspective, our company maintains a permanent stock of spare parts and consumables. Spare parts that are not in stock can be ordered and delivered within a period of 5 to 30 days.

Utilization of vegetable residues - rapeseed straw and forest residues - sawdust

People working in agriculture or forestry are well aware that these two activities generate a significant amount of waste. A large portion of this waste is either discarded or burned, which negatively impacts the environment. In an entrepreneurial spirit and as a method of recycling these abundant natural resources, I propose considering these waste materials as a source of income. With a rapeseed straw-sawdust pellet press or a pelletizing installation for vegetable residues, the waste can be transformed into a finished product at reduced costs.

Pellets can come in various sizes, ranging from 4-14 mm in diameter and 2-5 cm in length. They can have a bulk density of up to 750 kg/m³ and a pellet density of up to 1350 kg/m³.

Pellets can be produced from vegetable residues or forest residues using a pellet press, where the raw material is compressed in the channels of a die at high temperature. These pellets can be used as fuel in automated heating systems, effectively replacing both natural gas and coal.

Another aspect of straw pellets is that they can be used as bedding material for various animals such as chickens, horses, rabbits, cats, etc. Alfalfa pellets can be pelletized in combination with grains or other feed recipes. The reason is simple: pellet storage is easier than baling, and pelletized alfalfa can be mixed with other ingredients (such as wheat, barley, oats, corn) to create a valuable and cost-effective feed recipe. This mixture can be made directly on the farm, eliminating the need for an external feed factory.

Our company offers solutions and products on the European market related to pellet presses, pellet production machinery, and complete production lines for animal feed and cereal granules. We provide services such as delivery, installation, servicing, automation of complete pellet lines, post-warranty support, and spare parts.

Nowadays, people are searching for alternatives to fuel, which has become very expensive unjustifiably. Some try to substitute it by using wind energy, solar energy, hydropower, etc.

In the past, the cheapest and most convenient raw materials for obtaining energy and heating were wood and coal, which were later replaced by oil and natural gas. Unlike eco-friendly fuels, oil and natural gas are limited resources, more costly, and harmful to the environment. Until recently, straw was used for various activities in households, such as insulation, heating, animal feed, and even making straw bricks.

However, these methods of using straw are outdated and no longer applied. Currently, cereal production is increasing, which necessitates the improvement of the sector related to the processing of plant residues. Additionally, straw poses a challenge in soil processing after harvest.

According to statistical data, after barley harvest and processing, more than 1.5 tons of waste is generated per ton of finished product. For wheat, it's approximately 2 tons of waste, and for corn, it's over 6 tons.

Until now, this sector has not been developed. As a result, straw rots in the fields, and thousands of hectares of agricultural land with leftover straw after harvest are burned, causing global pollution.

In terms of energy, the proper processing of straw can be demonstrated by the fact that 1 kilogram of cereal straw has a calorific value of 3 kWh. This means that the same amount of energy can be obtained from 3 kilograms of straw as from one liter of diesel fuel or one cubic meter of natural gas.

Natural resources like cereal straw, which are easily obtained either through harvest or procurement, are five times cheaper than the cost of energy consumption from diesel fuel.

However, burning straw bales is not practical due to low efficiency (straw has low density and relatively high moisture content) and the inconvenience of handling large volumes of straw bales.

Therefore, briquetting straw is one of the most rational methods for utilizing bio-resources, as straw briquettes are more efficient in energy production than wood briquettes.

From a scientific point of view, straw is characteristic not only of dried cereal stems but also of vegetable stems, as well as flax, hemp, and other plants without leaves, inflorescence, and seeds.

Briquetted straw can serve as a universal biofuel for heating houses, greenhouses, farms, and industrial facilities.

Briquetting straw allows for solving issues related to:

- Preservation and storage of raw materials (regardless of the season - briquettes can be stored indefinitely if kept under special conditions)

- Briquette transportation

- Automation of loading into the furnace

- Animal feed

Processing and recycling waste, as well as briquetting straw, represent a promising sector both in the domestic and international markets. The delivery and commercialization of the finished product (briquettes) are much more profitable than selling raw materials.

Therefore, our company offers briquetting solutions/technologies, including mechanical straw briquette presses with flywheel-actuated piston, pellet granulator, pellet press, air dryer, bale shredding complex, and straw baler. We also provide services such as consulting, delivery, installation of briquetting and pelletizing equipment, post-warranty service, and automation of straw briquetting lines.

Our company intervenes in the European market with offers related to the commercialization of briquette and pellet production equipment, delivery, installation, service, post-warranty support, and spare parts.

Green spaces represent the primary source of natural resources, namely wood. Wood processing and manufacturing are highly developed branches of the industry. As a result of wood processing in carpentry, sawmills, timber factories, furniture and flooring factories, a significant amount of wood chips and wood waste is generated. Most of the wood waste is stored in the open air.

A portion of the wood chips is burned in boilers in its raw form, but the production of briquettes and pellets from wood chips is much more profitable.

The production of wood chip briquettes offers solutions for:

- Addressing the global issue of harmful emissions into the atmosphere

- Improving the condition of forests

- Caring for areas where companies operate in wood processing activities

- Others

Which is more efficient and cost-effective: briquette production or pellet production? Let's try to consider all the arguments for and against.

Machinery for briquette or pellet production?

Wood pellets require more expensive and complex machinery. Additionally, repairing and refurbishing pellet production machinery is costly and complicated, often requiring specialized service from the equipment manufacturer.

For briquette production, a mechanical wood chip briquette press such as BriqTech is required. These presses have a 30% lower cost compared to pellet production equipment while delivering the same performance.

Regarding raw material requirements, pellet production typically requires a smaller particle size (finer granulation) and excludes impurities. On the other hand, briquette production can accommodate larger-sized raw materials without any issues.

In terms of transportation and storage, pellets are fragile and can break or crumble with repeated handling. In contrast, briquettes retain their intact shape, and their fragmentation does not affect the burning capacity of the product.

The cost of pellets is much higher than that of briquettes due to the use of more expensive machinery and the need for skilled personnel.

As a product, pellets have a smaller market compared to briquettes. This is because pellets are primarily used in pellet boilers, while briquettes can be used in solid fuel boilers, industrial boilers, and directly in fireplaces, stoves, and other heating devices.

Acquiring biofuel from briquette and/or pellet production generates high income and promising prospects for the future.

Producing and utilizing energy from renewable sources for one's own activities, manufacturing fuel from biomass (e.g., pellet and briquette production) for commercial purposes as an integral part of projects funded by the European Union. It is likely that the Romanian government will pay attention by providing financial support to both producers and consumers of ecological fuel in order to reduce dependence on natural gas purchased from Russia or other countries. At the same time, the environment will be protected through the use of renewable and ecological fuel.

With the help of briquette production, we can provide bioenergy for both private homes and agro-industrial enterprises.

Our company intervenes in the European market with offers for the commercialization of wood chip briquette presses, briquette production machinery, pellet production lines, delivery, installation, service, automation of complete briquetting and pelletizing lines, post-warranty support, and spare parts.