Overview

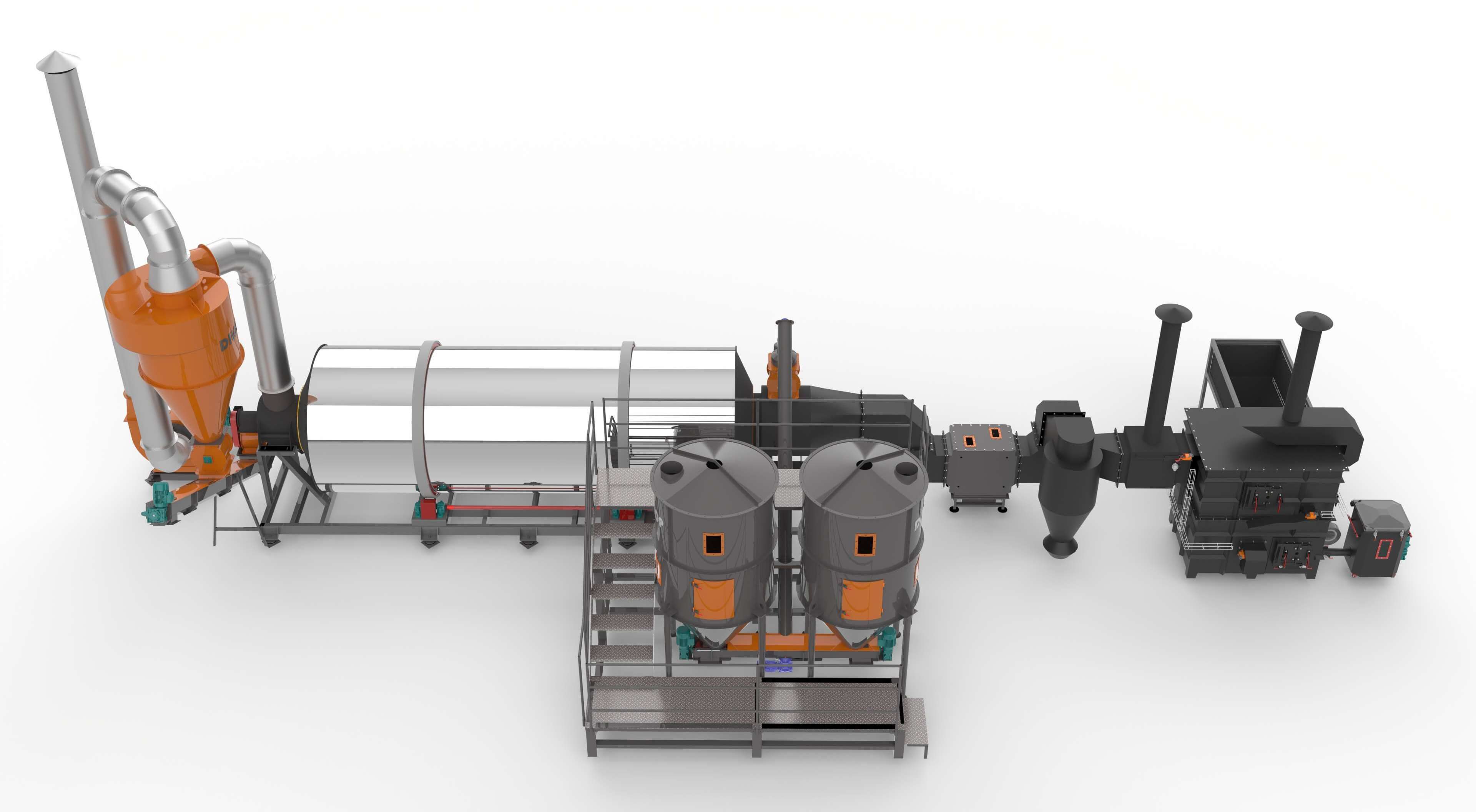

Universal Rotary Dryer SPB5-UNI Standard is designed for biomass pellet production, offering efficiency and reliability in operation.

Universal Rotary Dryer SPB5-UNI Standard – Performance and Versatility

The SPB5-UNI Standard rotary dryer is the ideal solution for the efficient drying of raw materials used in briquetting, pelletizing, and granulating. This equipment ensures a uniform and rapid drying process for a wide range of materials, including:

Straw, Alfalfa, Biogas digestate, Fermented manure, Wood chips, Grains, Sand, Other raw materials requiring drying

✔️ Ideal for the production of:

✅ Briquettes ✅ Pellets ✅ Granules (including granules for organic fertilizers)

SPB5-UNI Standard is designed for maximum efficiency, reducing the moisture content of raw materials and preparing them for optimal processing. It integrates perfectly into briquetting, pelletizing, and granulating lines, ensuring high production capacity.

Technical Features:

Cereals inlet moisture 24% –> outlet moisture 14%, productivity up to: 3000 kg/hour depending on the raw material

Wood chips inlet moisture 50% –> outlet moisture 14%, productivity up to: 600 kg/hour depending on the raw material

Straw inlet moisture 24% –> outlet moisture 14%, productivity up to: 1000 kg/hour depending on the raw material

Fermented manure inlet moisture 40-45% –> outlet moisture 14%, productivity up to: 600 kg/hour depending on the raw material

Thermal plant - Heat generator: 300KW

Fuel supply for the industrial thermal plant: briquettes, straw pellets, wood chips, sunflower husk, agro-pellets, lemm shavings

Total installed power: 18 kW

Three-phase current - 400V, coil voltage 24V/230V within +/- 5%, frequency 50 Hz

Length: mm Width: mm Height: mm

Weight: approximately 5500 kg

Dimensions and equipment level depend on the hall and requirements

Technology used since 2025

Working principle of the universal rotary dryer:

1. Industrial thermal plant using a mixed solid fuel with pyrolysis and hot air generator - constructed from stainless steel and high-temperature resistant chamotte

2. Cyclone separator for sparks and dust, electrostatic spark separator, and dust separator

3. Automated feeding hopper for raw materials*(pelleted briquettes, wood chip pellets, agro-pellets, lemm shavings) Volume - 1.6 - 3 m³

4. Three drying modes in a rotating tube with 3 spiral chambers

5. Fan, Cyclone with rotating valve with free fall

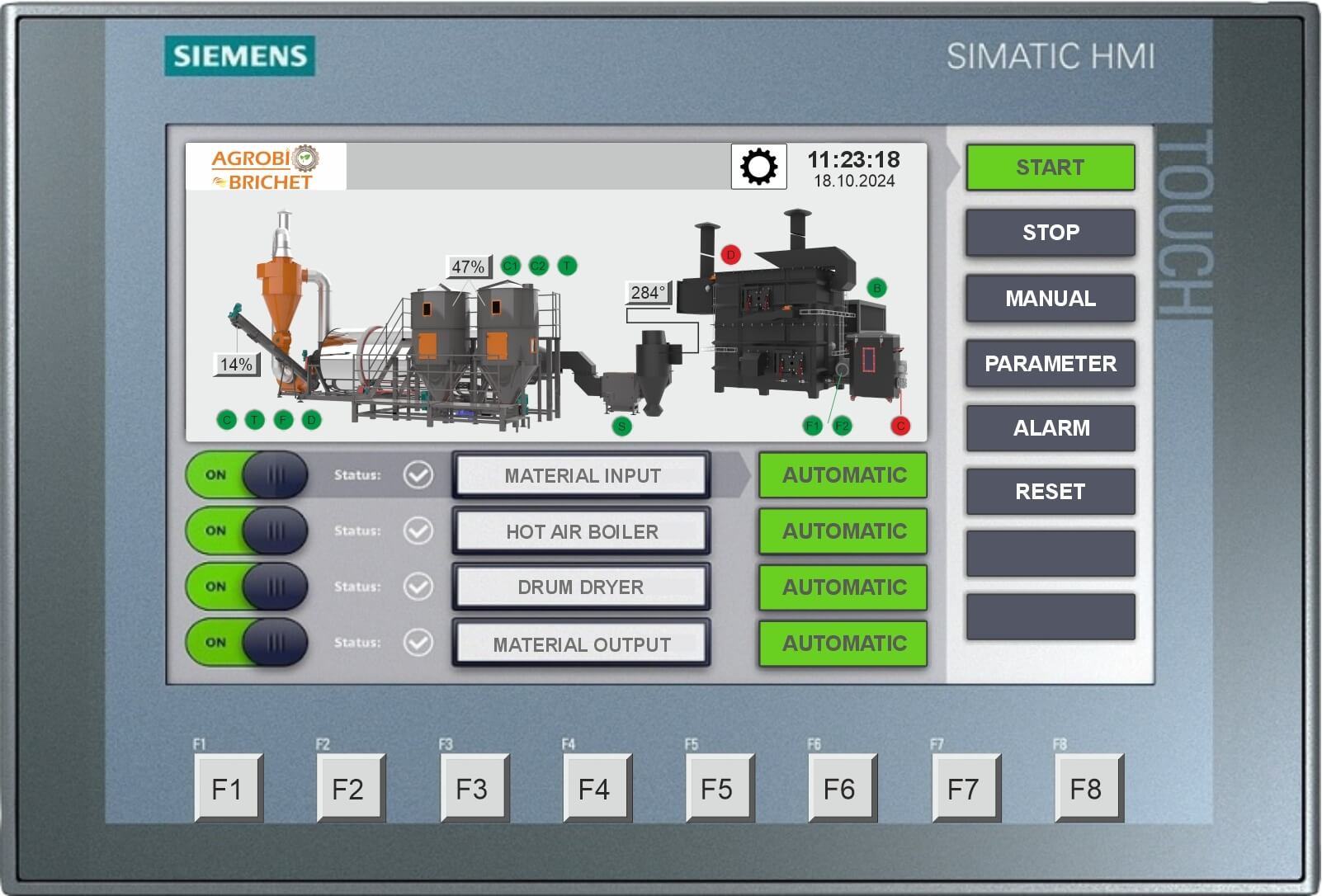

6. Control panel and automated PLC Siemens/Eaton operating program depending on the moisture content of the raw materials

7. Homogenization hopper for wet raw materials Volume 4.2 m³ - 2 units

Drying process: the wet raw material, with the help of hot air, passes through the rotating tube composed of 3 spiral drying chambers, where it mixes and loses moisture. Then, the dried raw material falls from the cyclone with a rotating valve, and the moist air is vented into the atmosphere through a fan.

Fully equipped Universal Rotary Dryer SPB5-UNI Standard:

1. Industrial thermal plant using mixed solid fuel with pyrolysis and hot air generator KDV300

2. Fuel storage tank 2.4 m³

3. Emergency flap for the chimney

4. Impurity separator with cyclone

5. Electrostatic separator for sparks *(Spark separator) and dust

6. Material storage tank - silo A, 4.2 m³

7. Material storage tank - silo B, 4.2 m³

8. Footpath construction

9. Horizontal collecting conveyor

10. Screw conveyor for dryer feeding

11. Solenoid valve for raw material dosing

12. Three-chamber drying cylinder

13. Support structure of the cylinder

14. Transport fan for evacuation

15. Interconnection pipes

16. Separator with cyclone

17. Material distributor - turnstile

18. Screw conveyor for unloading

19. Air and steam

20. Exhaust gases

21. Automatic ash removal

22. Electric control panel and automated command, PLC touchscreen, remote access

Control system – the entire device is controlled from a centralized switching panel with automatic adjustment, touchscreen control. After setting the necessary parameters, the rotary dryer can be fully automated, but with necessary control from the operator regarding the correctness and proper functioning of the entire assembly – Universal Rotary Dryer SPB5-UNI Standard. The electrical components mounted on the whole assembly comply with EU standards.

Optional accessories for the universal rotary dryer SPB5-UNI Standard:

Moisture sensors at the inlet and outlet

Mobile Compact Version of Universal Rotary Dryer SPB-UNI

Conclusion

Universal Rotary Dryer SPB5-UNI Standard represents a practical solution for valorizing biomass into eco-friendly fuel, with optimized efficiency and costs.