Overview

The industrial thermal boiler for mixed solid fuel with pyrolysis and hot air generator Series "KDV" is designed for biomass pellet production, providing efficiency and reliability in operation.

The industrial thermal boiler for mixed solid fuel with pyrolysis and hot air generator is an advanced heating system using staged combustion of solid fuels to achieve high efficiency and low emissions.

Main Features:

Mixed solid fuel – can use wood chips, pellets, briquettes, and agripellets from biomass waste.

Pyrolysis technology – increases combustion efficiency by thermally decomposing the fuel into combustible gas, leading to lower consumption and reduced emissions.

High efficiency – reaches 90-95% due to complete combustion of the resulting gases. Reduced emissions – combustion processes are optimized to minimize pollutants.

Hot air generator – distributes heat quickly and evenly, without needing a water heating system.

Advanced automation – boilers are equipped with sensors, dampers, and electronic controls for optimizing fuel consumption.

Optional mobile version - containerized click here

Advantages:

✔️ Three operating modes, programmable via PLC software

✔️ Fuel savings

✔️ High efficiency, due to pyrolysis

✔️ Cost reduction on fuel by using local biomass.

✔️ Increased energy efficiency through staged combustion technology.

✔️ Lower ecological impact compared to conventional solid fuel boilers.

✔️ Rapid heating of large spaces

The industrial thermal boiler for mixed solid fuel with pyrolysis and hot air generator Series "KDV" is equipped with a stainless steel heat exchanger designed for the production and distribution of hot air in systems requiring drying with clean air, free of combustion gases and impurities. These types of thermal boilers are intended for drying products for the food or feed industry and digestate from biogas, as well as other materials requiring clean air and controlled temperatures in the drying process. In specific applications, where the use of combustion gases is permitted, the programmable software of the KDV boiler allows operation in three modes, connecting combustion gases to the heat exchanger via an adjustable damper, thus enabling their introduction into the airflow used for drying. In this configuration, the temperature generated by the heat exchanger can range between 50-150 °C, and by adding combustion gases to the system, the drying air temperature can be increased up to 500 °C, and in extreme conditions, up to 550 °C. The industrial thermal boiler for mixed solid fuel with pyrolysis and hot air generator is universal, suitable for the drying of agricultural products as well as other materials that can withstand high temperatures during the drying process.

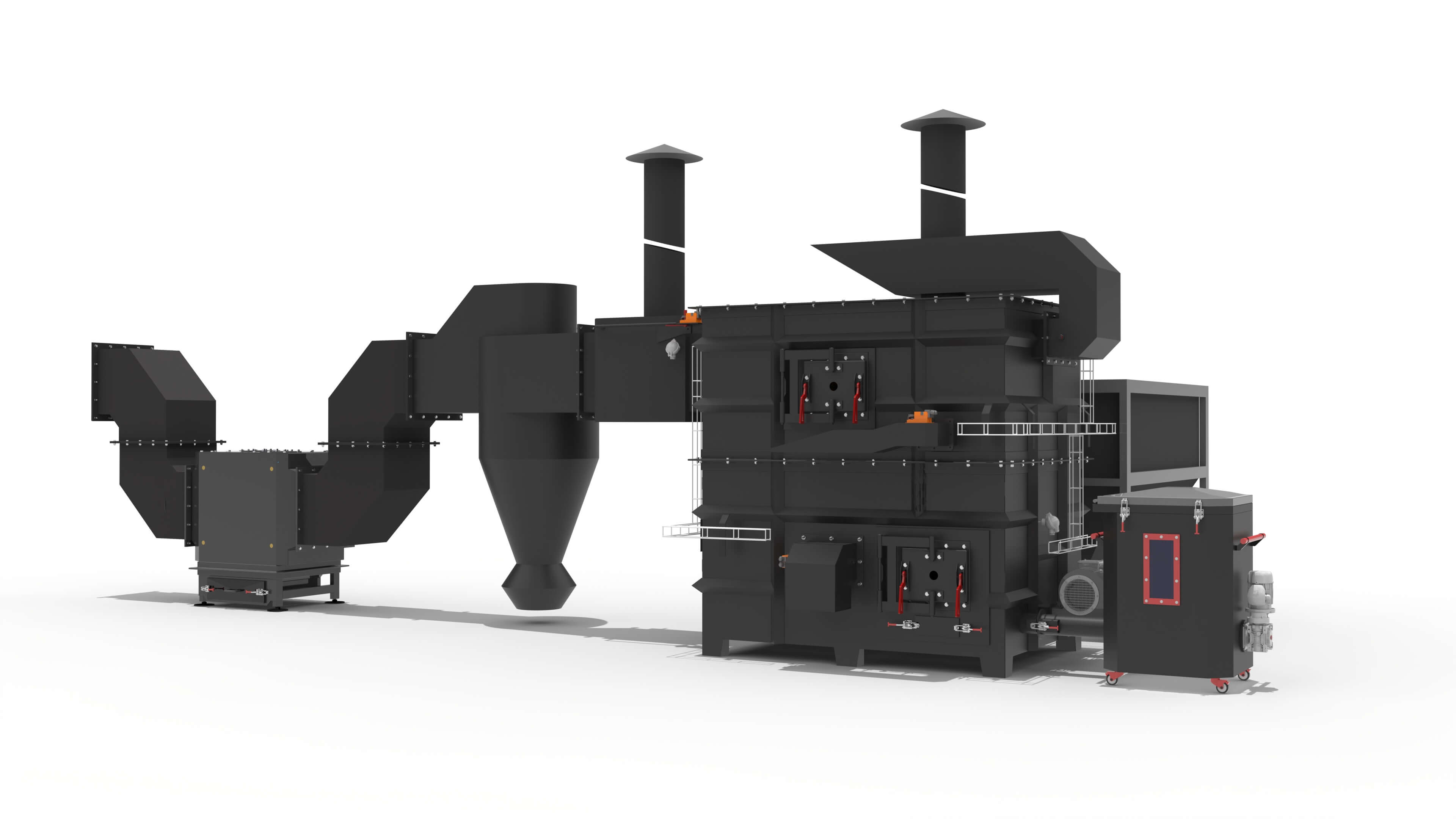

Industrial thermal boiler for mixed solid fuel with pyrolysis and hot air generator Series "KDV"

Main air intake for heating the heat exchanger

Combustion chamber *(firebox)

Adjustable damper, control of air intake in the combustion chamber

Inspection and service door for the heat exchanger

Adjustable damper, control of the outlet temperature

Burning chamber fan

Combustion chamber fan

Adjustable damper, emergency safety for exhaust gas release

Cyclone separator for sparks and dust

Electrostatic spark separator and dust separator

Adjustable outlet temperature: 50-500 °C, max. 550 °C mode I

Adjustable outlet temperature: 50-150 °C, max. 200 °C mode II

Adjustable outlet temperature: 50-600 °C, max. 650 °C mode I+II

Exhaust gas pipe from the damper, emergency safety

Container for filtered particulates and dust

Container for separated dust particles

Automatic ash removal system, with connection possibility to an external ash tank

Exhaust gas pipe from the heat exchanger

Solid fuel tank with automatic supply to the firebox

Electric control panel and automated control, PLC touchscreen, remote access

Containerized - mobile version

Technical specifications:

| Model |

Power |

Outlet Temperature, Mode I |

Air Yield, Outlet m3/hour |

Outlet Temperature, Mode II |

Air Yield, Outlet Hot Generator, m3/hour |

Electric Power Consumption |

Boiler Dimensions (L x W x H) |

Weight |

| KDV 150 |

150 KW |

500 °C |

5600 |

150 °C |

4650 |

2.2 kW |

1150 x 800 x 1200 |

1180 kg |

| KDV 300 |

300 KW |

7500 |

6250 |

2.6 kW |

1210 x 925 x 1200 |

1690 kg |

| KDV 500 |

500 KW |

8000 |

6700 |

2.8 kW |

1450 x 1050 x 1300 |

2820 kg |

| KDV 700 |

700 KW |

8450 |

7050 |

2.8 kW |

1450 x 1300 x 1300 |

4150 kg |

| KDV 900 |

900 KW |

9600 |

8000 |

3.4 kW |

1960 x 1425 x 2100 |

5420 kg |

| KDV 1300 |

1.3 MW |

11500 |

9600 |

3.8 kW |

2250 x 1675 x 2180 |

7380 kg |

| KDV 1500 |

1.5 MW |

12700 |

10700 |

3.8 kW |

2250 x 1925 x 2180 |

8540 kg |

| KDV 1800 |

1.8 MW |

14500 |

12100 |

4.2 kW |

2710 x 2175 x 2220 |

10890 kg |

| KDV 2200 |

2.2 MW |

16800 |

14200 |

4.8 kW |

2960 x 2300 x 2220 |

13190 kg |

| KDV 2500 |

2.5 MW |

20100 |

16750 |

4.8 kW |

3210 x 2425 x 2220 |

15080 kg |

Conclusion

The industrial thermal boiler for mixed solid fuel with pyrolysis and hot air generator Series "KDV" represents a practical solution for utilizing biomass as eco-friendly fuel, with optimized efficiency and costs.