Overview

Industrial Solid Mixed Fuel Thermal Boiler with Pyrolysis Series "KD" is designed for the production of biomass pellets, offering efficiency and reliability in operation.

Industrial thermal boiler using mixed solid fuel with pyrolysis is an advanced heating system that utilizes staged combustion of solid fuels to achieve high efficiency and low emissions.

Main features:

Mixed solid fuel – can use wood chips, pellets, briquette pastilles, agro-pellets from biomass waste.

Pyrolysis technology – thermal decomposition of the fuel in low-oxygen conditions, generating a flammable gas that burns separately for better efficiency.

High efficiency – reaches 90-95% due to complete combustion of the resulting gases. Low emissions – combustion processes are optimized to reduce pollutants.

Advanced automation – thermal boilers are equipped with sensors, dampers, and electronic control for optimizing fuel consumption.

Advantages:

✔️ Reduced fuel costs by utilizing local biomass.

✔️ Increased energy efficiency through staged combustion technology.

✔️ Lower ecological impact compared to conventional solid fuel boilers.

Industrial thermal boiler using mixed solid fuel with pyrolysis Series "KD" are structurally assembled so that the combustion gases are used to create the drying environment, which are subsequently filtered with the help of a centrifugal cyclone and an electrostatic filter. They are designed for distributing warm air throughout the system, where it is possible to dry using filtered combustion gases. With this version, temperatures of up to 480-500 °C can be achieved, exceptionally up to 550 °C for drying non-flammable materials. Boiler Series "KD" can be used to dry raw materials such as sawdust and other substances that can tolerate higher temperatures for drying.

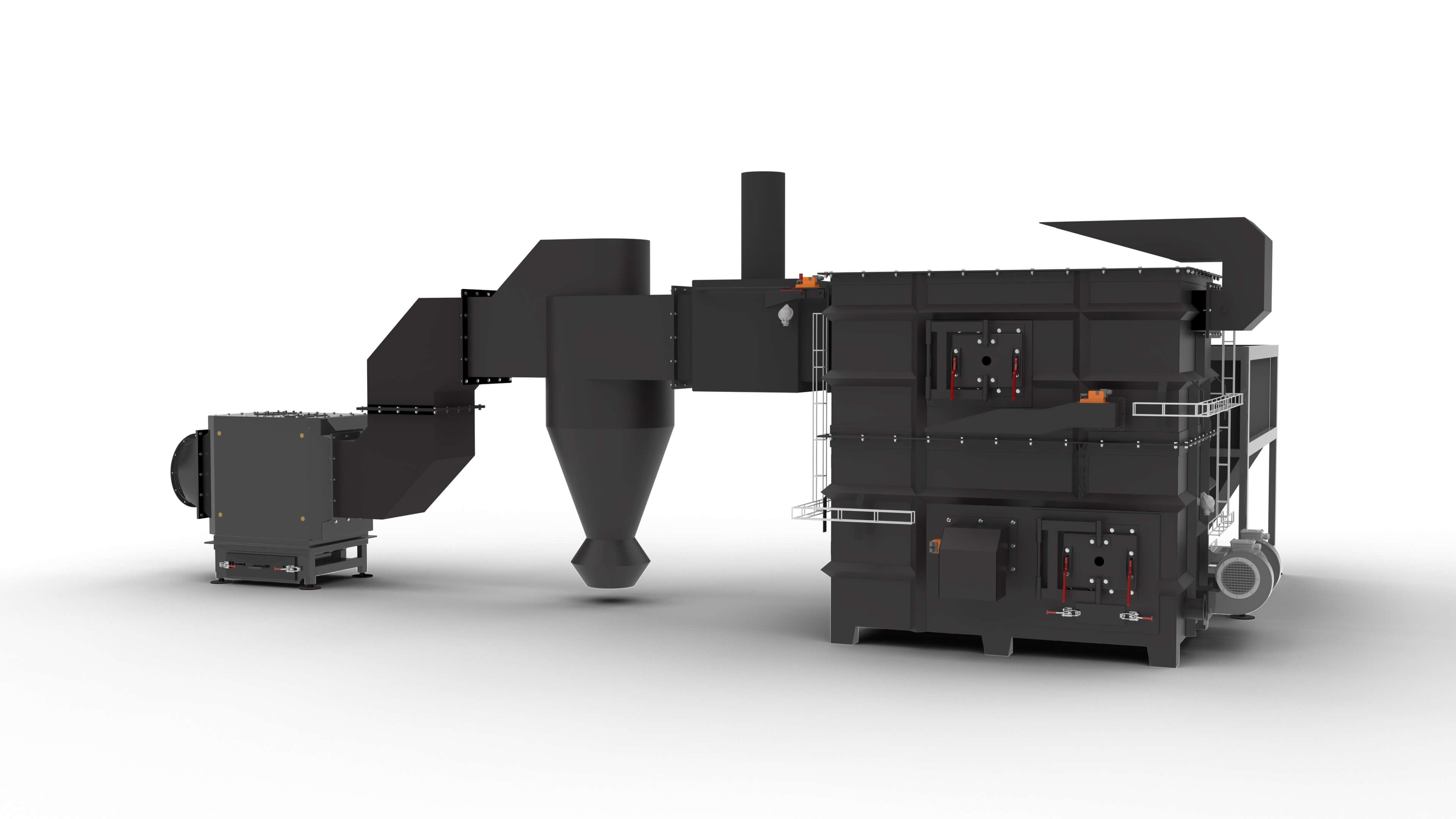

Industrial Solid Mixed Fuel Thermal Boiler with Pyrolysis Series "KD"

Main air intake for heating

Burning chamber *(firebox)

Regulating damper, control for air intake in the burning chamber

Filtration and post-combustion chamber

Regulating damper, control of output temperature

Burning chamber fan

Combustion chamber fan

Regulating damper, safety for emergency exhaust of burnt gases

Cyclone spark and dust separator

Electrostatic spark separator and dust separator

Container for separated dust particles

Adjustable output temperature 50-500 °C, max. 550 °C

Emergency flue gas discharge

Cyclone for filtered particles and dust

Automatic ash removal system, with the possibility of connection to an external ash tank

Solid fuel tank with automatic feeding of the firebox

Electric control panel and automated command, PLC touchscreen, remote access

Technical features:

| Model |

Power |

Output Temperature |

Air Efficiency, Output |

Electric Energy Consumption |

Boiler Dimensions L X W X H |

Weight |

| KD150 |

150 KW |

480-500 °C |

5600 m3/hour |

2.2 kW |

1150X800X1200 |

1120 kg |

| KD300 |

300 KW |

7500 m3/hour |

2.6 kW |

1210X925X1200 |

1620 kg |

| KD500 |

500 KW |

8000 m3/hour |

2.8 kW |

1450X1050X1300 |

2750 kg |

| KD700 |

700 KW |

8450 m3/hour |

2.8 kW |

1450X1300X1300 |

3950 kg |

| KD900 |

900 KW |

9600 m3/hour |

3.4 kW |

1960X1425X2100 |

5320 kg |

| KD1300 |

1.3 MW |

11500 m3/hour |

3.8 kW |

2250X1675X2180 |

7290 kg |

| KD1500 |

1.5 MW |

12700 m3/hour |

3.8 kW |

2250X1925X2180 |

8440 kg |

| KD1800 |

1.8 MW |

14500 m3/hour |

4.2 kW |

2710X2175X2220 |

10780 kg |

| KD2200 |

2.2 MW |

16800 m3/hour |

4.8 kW |

2960X2300X2220 |

12990 kg |

| KD2500 |

2.5 MW |

20100 m3/hour |

4.8 kW |

3210X2425X2220 |

14880 kg |

Conclusion

Industrial Solid Mixed Fuel Thermal Boiler with Pyrolysis Series "KD" represents a practical solution for utilizing biomass as eco-friendly fuel, with optimized efficiency and costs.